Imisonto machining izinto

- Inkqubo yokuqengqeleka komsonto

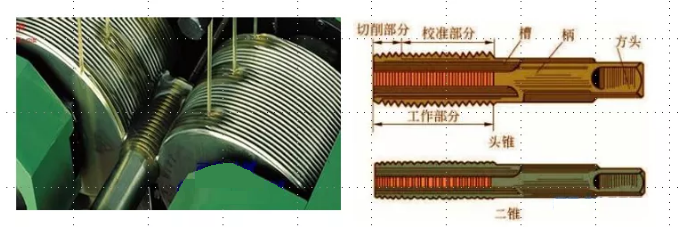

(1) Umgaqo osisiseko wentambo eqengqelekayo

Ukujija umsonto yinkqubo ye-deformation yeplastikhi, ekucofa umphezulu wamavili aqengqelekayo okanye umsonto ojikelezayo kwipleyiti kwinto engenanto yamalungu kubushushu begumbi ukuze zonke izinto ezantsi kumsonto zicudiselwe phezulu kumazinyo omsonto yenza umsonto kwinxalenye.

Umsonto ojikelezayo uqhutywa ngokomgaqo wobungakanani obungenakufikeleleka, ke ukuchaneka komsonto kunxulumene nobungakanani bendawo engenanto.

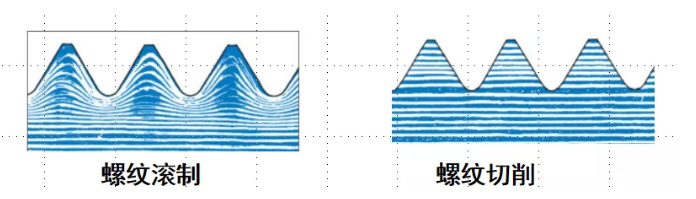

(2) Inkqubo yokuqhubekeka

Umsonto wokusika umsonto ojikeleziweyo

(3) Iimpawu:

• Umsonto owenziwe ngokuqengqeleka awusiki kwaye usike ifayibha yentsimbi yoqobo;

Ukuchaneka komsonto ophezulu;

• Ubulukhuni kunye noburhabaxa bomgangatho wezantsi onomsonto kuphuculwe ngokuqina kobandayo obandayo;

• Ngaxeshanye, kukho intsalela yoxinzelelo loxinzelelo, ke amandla okucheba kunye namandla okudinwa anyuswe nge-30% - 100% xa kuthelekiswa nomsonto wokusika. Nangona kunjalo, emva konyango lobushushu, ukuqina kunye noxinzelelo lwentsalela yokusebenza koxinzelelo kuya kuthi shwaka;

• Ifanelekile kwimveliso yobunzima;

• Ukuqengqeleka kwemisonto kunokwahlulwa kube kukuqengqeleka phambi kwonyango lobushushu kunye nonyango lobushushu ngaphambi kokuqengqeleka;

(kufanele kuqatshelwe ukuba xa ubunzima bezinto buphezulu kune-hrc36, izinto ezingafunekiyo kufuneka zongezwe (i-42CrMo). Amanye amashishini afuna unyango lobushushu ngaphambi kokuqengqeleka komsonto.)

- Inkqubo yokurabha umsonto

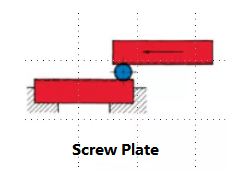

(1) Ukuqhutywa kweplate yokuqengqeleka komsonto

Ukuqengqeleka komsonto kukulungisa isicwecwe esinye, kwaye enye ipleyiti eshukumayo iyahamba ibuye umva ukuqhuba imveliso ukuba ihambe. Isikhewu esingenanto senziwe ngengca ngeplastikhi ukwenza umsonto ofunekayo.

• Ifanelekile iM1 ~ M30

• Ukuchaneka kungaphantsi kunesondo eliqengqelekayo kwaye ukusebenza kwalo kuphezulu.

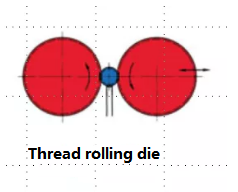

(2) Ukuziqengqa ngeroli yocingo

Umsonto ukuziqengqa kukusebenzisa iziqhoboshi ezihambelanayo ezijikelezayo, ukujikeleza okuhle, usebenzisa i-extrusion ukuvelisa i-deformation yeplastikhi yemveliso ukwenza umsonto ofunekayo.

• Ilungele ubungakanani obukhulu kunye nentambo ende, efanelekileyo ngentambo epheleleyo yentonga.

Ukuchaneka kuphezulu.

• Ukusebenza kwemveliso kuphantsi noko.

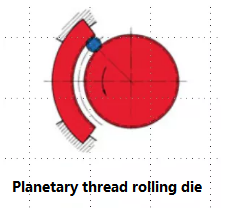

(3) yemihlaba yemisonto kaloliwe die

Itafile yemisonto ye-arc ayihambisi, i-screw roller ijikeleza ngesantya esiphezulu, ikhupha iscrew blank

• Ilungele ubungakanani obuncinci (uhlobo lomatshini)

• Ukusebenza okuphezulu kwemveliso

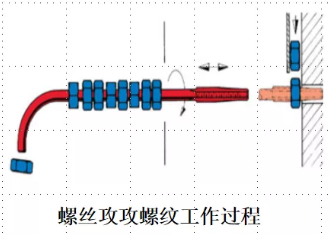

- Indlela yokusika yompompo wangaphakathi wentambo

Ukulungiswa kwemisonto yangaphakathi isebenzisa itephu ukucofa kwi-nut ukusika umsonto. Ukuthanjiswa okufanelekileyo kuyadingeka ngexesha lokucofa ukuphucula imeko yokusika.

• Ukuchaneka komtya wangaphakathi wenut kuxhomekeke kwisikrini sokuchwetheza ngokuchanekileyo, izinto, isantya kunye nokuthambisa.

• Umsonto owandisiweyo wesinyibilikisi eshushu ubhekisa kunyuko lobubanzi bepara yetephu yokujija.

Ixesha Post: Dec-04-2020